The Graze Factory Project

Graze is a hugely popular UK-based snack company offering both subscription boxes and one-off products stocked in leading retailers. As they offer over 200 different varieties of snack combinations, it is imperative for their factory to remain fully-functioning, safe and efficient.

The team at Graze contacted Rapide to help with renovating the largest area of their factory. They provided the Rapide specialised with a specification on the flooring type that they required, along with their unique requirements.

Products Used

- Concrete Foundation

- Resin MMA Quartz Screed

- Anti-Slip Top Coat

1.

The Proposal

When Graze initially contacted Rapide, they wanted polyethylene resin, along with a full drainage system redesign. However, having many years of experience in the industry, we instantly knew that this wouldn’t be the best route for the client. Due to the constant footfall that the premises would experience, the polyethylene wouldn’t last as long as the client had hoped, meaning that they would have to spend money replacing the flooring again in a few years. With this in mind, we suggested changing the specification to swap the polyethylene for our Resin MMA Quartz Screed. This would be considerably more durable, stronger and able to withstand constant wear and tear.

2.

The Planning

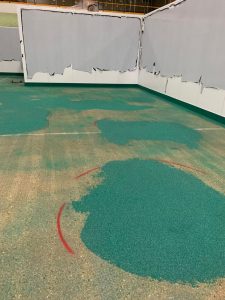

Before we could go ahead with installing any layers of resin, we had to remove the current flooring using expert machinery. Once we had a blank canvas to work from, it was imperative for us to draw out a design and add a template to the flooring. We used spray paint to draw arrows onto the floor, which would help us to work out what direction water needed to flow to ensure that they reached the drain points effectively.

3.

The Delivery

Once we were happy with the template, we could then begin to install the various layers of flooring. First and foremost, a screed was added with a slight gradient, which would enable any spilt liquids to stream straight towards the closest drainage point. Next came the cement and underlay, which would add a robust surface for the resin to lay on top, allowing the flooring to remain durable and damage-free. Lastly, the Resin MMA Quartz Screed could be carefully applied to the surface. The client chose a green coloured resin which would blend seamlessly with their premises.

4.

The Closing

To finish the flooring installation, we installed expansion joints. The expansion joints are designed to allow the flooring to move without cracking. With time, change in temperature and constant tear, it is inevitable for the flooring to begin to move naturally. So, to overcome this hurdle and avoid cracking, the expansion points were a vitally important component. A final non-slip coating was then applied, which would prove to be considerably more slip-resistant than the client’s original request of polyethylene flooring.

What our clients are saying

Feedback From Graze

Rapide's product exceeded our expectations for creating an easy wash-down floor in a hygienic environment and a hard-wearing floor.